The Propulsion Revolution: How Tomorrow’s Engines Are Redefining Space Travel

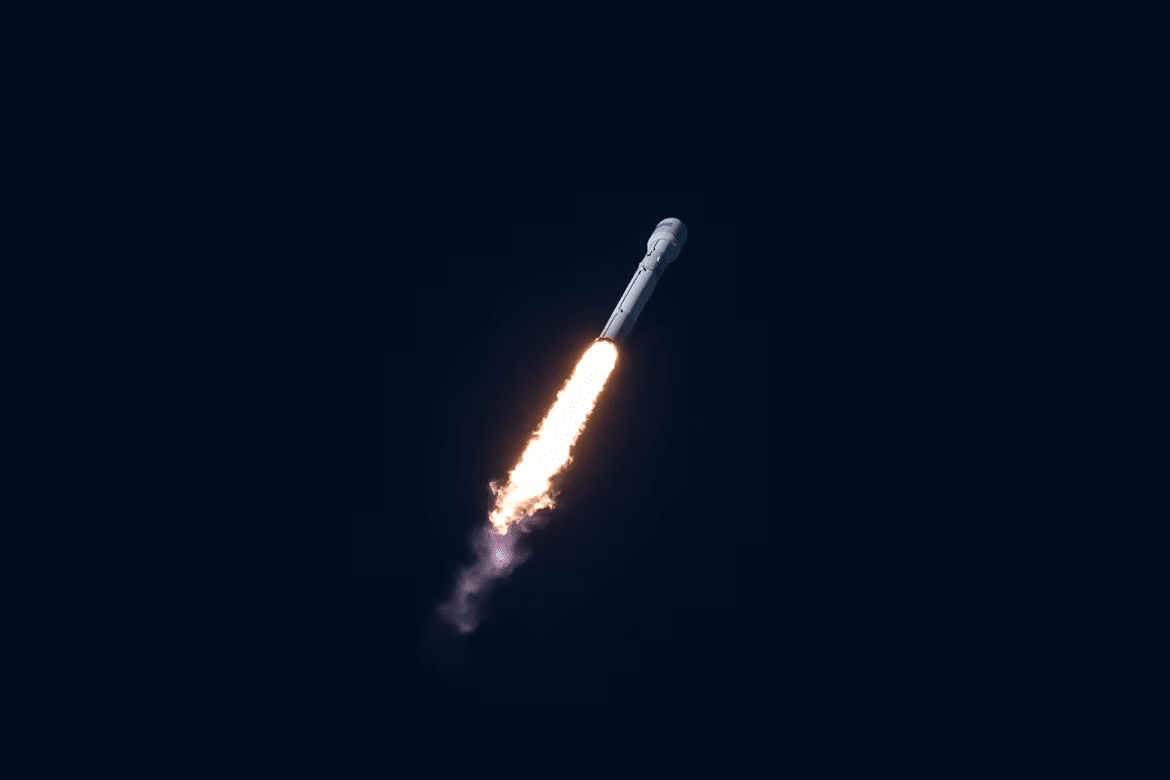

In the last 18 months, propulsion technology has taken a sharp turn from evolutionary to revolutionary. A new wave of experimental engines, plasma-based thrusters, and 3D-printed mini-rockets is not just reshaping how we get to space but redefining what’s possible once we’re there.

This post dives into some of the most exciting recent milestones in propulsion, from the atmospheric to the interstellar.

1. Rotating Detonation Engines: The Shockwave Solution

In May 2025, Venus Aerospace completed the first U.S. flight test of a Rotating Detonation Rocket Engine (RDRE), a type of propulsion that uses a continuous, spinning shockwave to combust fuel. Unlike traditional engines, which burn fuel in a steady chamber, RDREs detonate it in a circular loop.

Why it matters:

-

Up to 25% more efficient than conventional engines

-

Lighter, more compact, and simpler construction

-

Capable of extreme performance in both hypersonic aircraft and space vehicles

Next step: Venus is developing its VDR2 engine, aiming to power Mach 4 aircraft by 2026. In parallel, GE and DARPA are exploring RDREs for dual-mode propulsion (subsonic → hypersonic).

2. Plasma Thrusters: Pushing the Limits of Ion Propulsion

In March 2025, ISRO announced a milestone: it ran its Stationary Plasma Thruster (SPT) continuously for over 1,000 hours. This electric propulsion system uses ionised xenon gas to provide thrust, perfect for station-keeping and orbit-raising.

Why it matters:

-

Delivers 6× higher specific impulse than chemical engines

-

Low-thrust but ultra-efficient for long-duration space missions

-

Enables lighter satellites and extended operational life

These systems will likely underpin the next decade of LEO satellite constellations, interplanetary probes, and space station manoeuvring.

3. 3D-Printed Rocket Engines: Propulsion at Startup Speed

Startups like ABRA Space (UK) and Impulse Space (US) are rapidly maturing 3D-printed propulsion systems, ranging from mini-solid boosters to liquid bipropellant motors.

Recent standouts:

-

AURA 24 and SKYLAB 24 engines from ABRA Space are fully printed and tailored for CubeSat and micro-launch platforms.

-

Impulse’s micro lander engines are designed to survive precision landing burns on the Moon and Mars.

Key advantages:

-

Reduced manufacturing time and costs

-

Custom geometries for enhanced cooling and combustion

-

Lightweight, scalable thrust for small payloads and rapid iteration

4. The Fusion Future & Experimental Concepts

Though still in prototype stages, nuclear thermal propulsion and fusion-based drives are regaining momentum:

-

NASA and DARPA’s DRACO project targets an operational nuclear thermal spacecraft engine by 2027

-

Fusion startups like Pulsar Fusion (UK) aim to harness high-speed plasma exhaust to achieve interplanetary travel times measured in weeks, not months

These propulsion methods could unlock human exploration of Mars and beyond, shrinking deep-space missions from years to months.

Final Thoughts: Propulsion Isn’t Just Faster, It’s Smarter

What makes this moment revolutionary isn’t just raw speed or efficiency; it’s the mechanical intelligence behind it all:

-

Shockwaves replacing steady-state burns

-

Electromagnetic fields replacing combustion

-

Additive printing replaces welds and bolts

These changes are fundamentally mechanical in nature, and they represent a reimagining of how we engineer force and motion.

If you’re a mechanical engineer or propulsion enthusiast, now is the time to tune in: the next giant leap isn’t just about where we go, but how we get there.