The Second Life Revolution: Circular Supply Chains for Electric Mobility

As electrification accelerates, the mobility industry is facing a new kind of challenge: what happens when electric vehicle components reach the end of their first life? Batteries, motors and power electronics are rich in valuable materials, yet without proper recovery strategies they risk becoming the next major source of industrial waste.

Forward thinking OEMs and suppliers are no longer treating this as an afterthought. Instead, they are embedding circular supply chain models that capture material value, reduce dependency on volatile raw material markets and support sustainability targets.

From Linear to Circular Thinking

Traditional supply chains have been built on a linear model: extract, manufacture, distribute, use and discard. Electrification has exposed how fragile this model can be, given the finite supply of critical minerals such as lithium, cobalt and nickel.

A circular approach closes the loop by returning used materials and components into production, turning waste into input. This is no longer just an environmental initiative; it is a strategic imperative for supply chain resilience.

How Circular Models Are Taking Shape

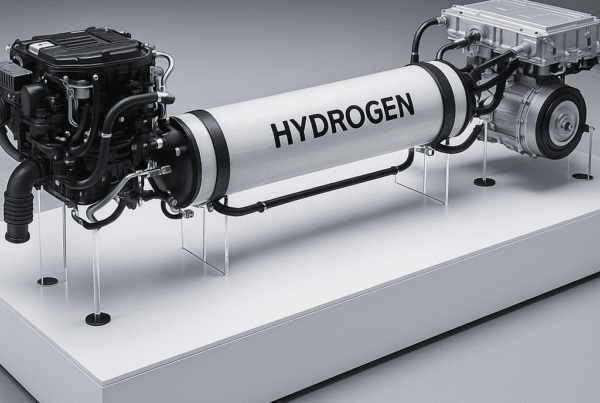

- Battery Recycling and Second Life

- OEMs are partnering with recycling specialists to recover materials from end-of-life batteries and reuse them in new cells. Some are developing second-life applications, where used EV batteries power energy storage systems for homes or grids.

- Remanufacturing Electric Motors and Electronics

- Motor and inverter cores can be reconditioned and reused, extending component life while cutting carbon and cost. Procurement teams are now writing remanufacturing clauses into supplier contracts to ensure a steady flow of reusable parts.

- Designing for Disassembly

- Engineering teams are collaborating with procurement to ensure that new EV components are easier to dismantle and recycle. This design-for-circularity mindset is creating new supplier standards across the mobility value chain.

- Digital Traceability

- Blockchain and serialisation tools are being used to track materials from origin to end of life, ensuring compliance with environmental regulations and proving recycled content in new products.

The Business Case for Circularity

Circularity is reshaping cost structures and supplier relationships. Recovered materials reduce exposure to volatile commodity markets, while recycled inputs often have a lower carbon footprint, a factor now influencing procurement decisions and ESG scoring.

Moreover, regulatory frameworks such as the EU Battery Regulation and similar policies in North America are pushing OEMs to demonstrate responsible sourcing and material recovery. Early adopters will not only ensure compliance but gain competitive advantage through cost stability and reputational strength.

Closing the Loop, Opening New Value

Circular supply chains are no longer an aspiration; they are becoming a competitive necessity in the electrified mobility landscape.

The companies that succeed will be those that view end-of-life as the beginning of a new value cycle, where every battery, motor and microchip has the potential to drive the next generation of sustainable mobility.